Greubel Forsey: haute horlogerie poetry

26 February 2024The concept of independent watchmaking is too important not to be taken seriously. Antonio Calce, CEO & Shareholder of Greubel Forsey, knows this, as in 2022 he carried out a sort of buyback from Richemont, repurchasing 20% of the company shares that were owned by the luxury group since 2006, that is two years after the foundation of their company. Only two years. Richemont had seen a lot of potential in Greubel Forsey’s quality, but then Calce decided that independence was a more important value than belonging to a large group. A natural choice, if you look at the history of this incredible brand.

THE ORIGINS OF GREUBEL FORSEY

Because Greubel Forsey is a special case even for the very high standards of independent high-end watchmaking, a sector in which obsessive attention to detail and personal interpretations of the watchmaking art are the norm. The company produces a limited number of watches per year and each of them is significantly different from those produced by any other brand.

Above all, Greubel Forsey is famous among collectors and enthusiasts for its tourbillon watches, because since its foundation the brand has been at the forefront of the innovation and design of this very noble complication. But the company also created top complications, including the grande sonnerie and a perpetual calendar with equation of time.

Greubel Forsey was founded in 2004, but its story actually began much earlier. It was 1992 when Robert Greubel and Stephen Forsey met in Le Locle, Switzerland, in the Renaud & Papi grand complications atelier. Forsey, English, had studied watchmaking at the prestigious WOSTEP (Watchmakers of Switzerland Training and Educational Program) in Neuchâtel and worked at Asprey’s in London, in the restoration department. Robert Greubel, a French watchmaker from Alsace, had come to Renaud & Papi after a period at IWC, where he worked on the 1990 Grande Complication: a watch with a minute repeater, chronograph and perpetual calendar with a four-digit year display.

It is no coincidence that the two met at Renaud & Papi. At the end of the 1990s and the beginning of the 2000s, the atelier was a sort of advanced specialization school for young independent watchmakers. Besides Robert Greubel and Stephen Forsey, other people who would later have brilliant careers in watchmaking also attended the atelier. Among them, Andreas Strehler, the Grönefeld brothers, Anthony de Haas of A. Lange & Söhne, Carole Forestier-Kasapi, current director of the movements department at TAG Heuer.

There, the ground was fertile for this generation of young, talented watchmakers with lots of imagination and ambition. Stephen Forsey and Robert Greubel quickly acquired solid experience in the field of fine watchmaking, and in 2001 they left the atelier to found their own company, specializing in complications and called CompliTime.

These were the years of the full renaissance of mechanical watchmaking and the birth of ‘hyper-watches’: the right time, the two thought, to launch their own brand. Thus, in 2004, Greubel Forsey was born and began its adventure by immediately making clear what kind of watchmaking it was aspiring to: the one expressed in the brand’s first watch, the Double Tourbillon 30º.

THE DOUBLE TOURBILLON 30º

The two could only start from there. Not having a tourbillon in your collection – if you are a haute horlogerie brand – is unthinkable, despite the fact that most tourbillon wristwatches have not significantly updated the fundamentals of design since this complication was invented. It was precisely here that Greubel Forsey’s stroke of genius was expressed.

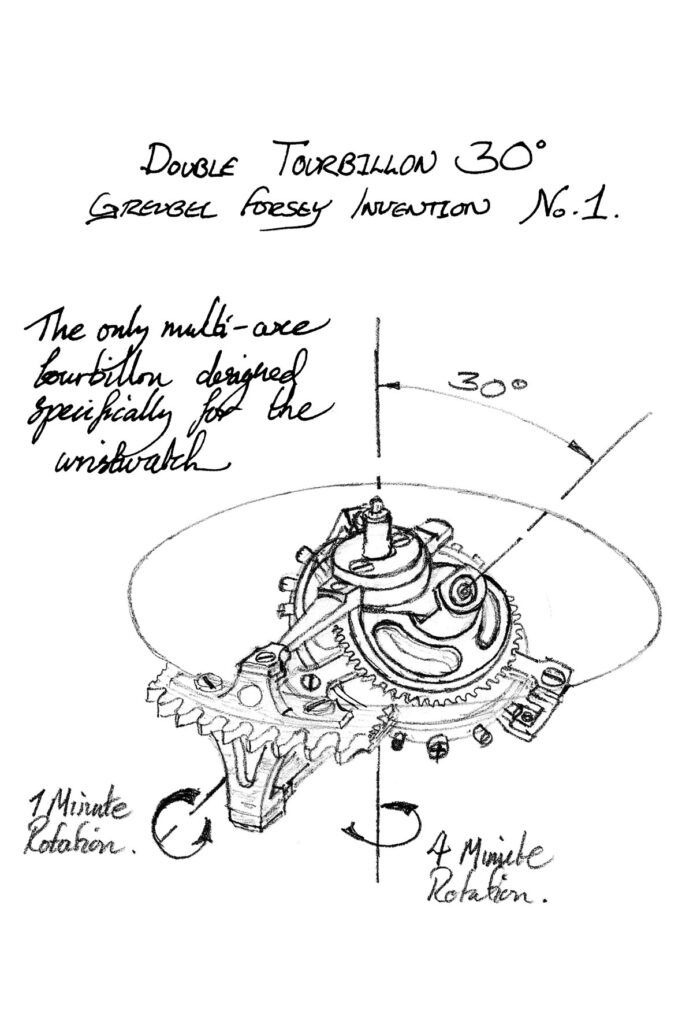

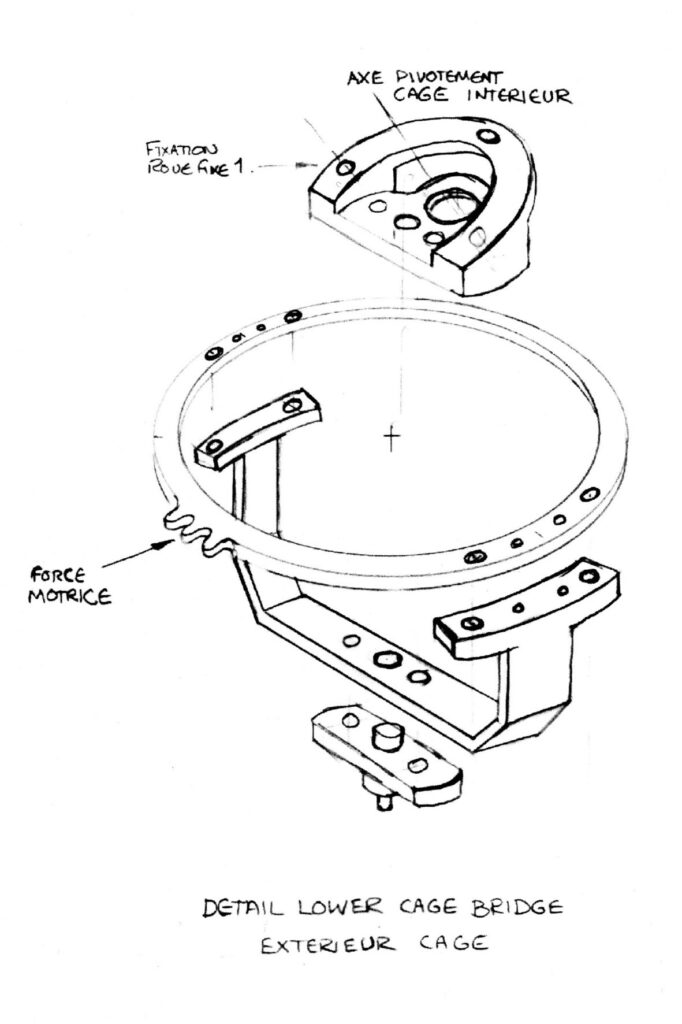

The Double Tourbillon 30º is not a conventional tourbillon. It is made up of two carriages instead of one: the inner one rotates once every sixty seconds, the outer one once every four minutes. This is what makes the Double Tourbillon 30º a ‘double tourbillon’: the fact that it is equipped with two carriages, one rotating inside the other, and at different speeds.

But what really changes the rules of the game is the fact that the balance axis is not located – as almost always happens in tourbillons but also in conventional watches – on the vertical axis of the movement: it is offset by thirty degrees. This type of design ensures that, regardless of the position the watch is in, the regulating organs are never in the most extreme positions for more than a moment.

The maximum gear deviation in a watch occurs between the perfectly flat and perfectly vertical positions; since the tourbillon never remains in either position for more than a fraction of a second, the most extreme deviations can be avoided. This means that, while tourbillon watches existed before this timepiece, the Double Tourbillon 30º can be considered the first designed specifically for the conditions of a wristwatch to be used daily.

DOUBLING THE GREUBEL FORSEY TOURBILLON: QUADRUPLE TOURBILLON

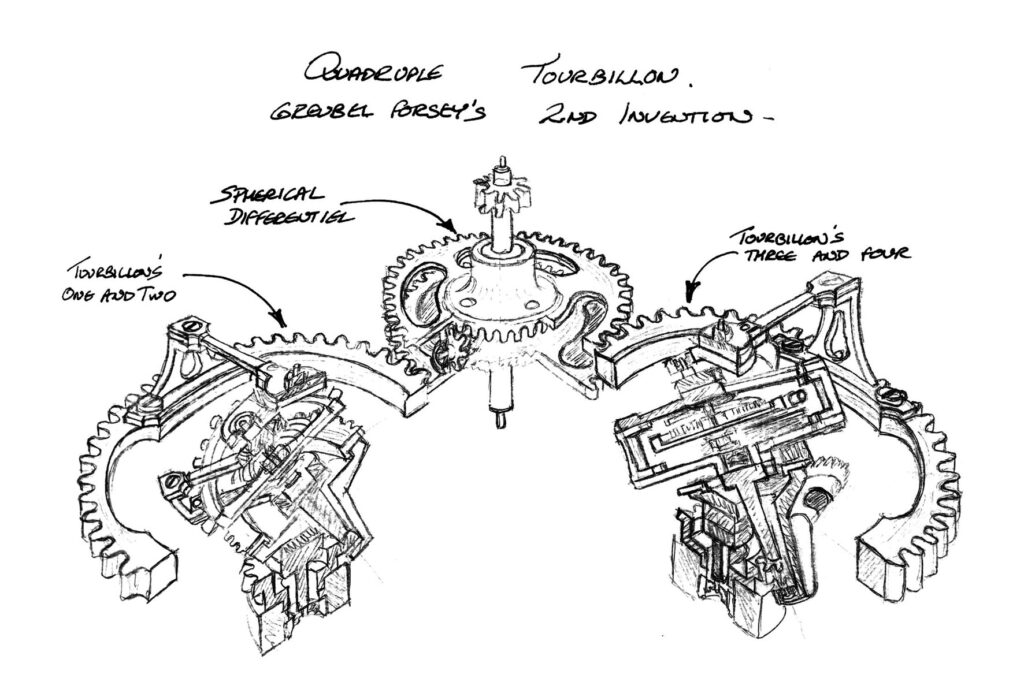

The second invention is the Quadruple Tourbillon: two 30º Double Tourbillon systems within the same watch. The thought behind the Quadruple Tourbillon is exactly the same as the Double Tourbillon 30º, but the desire to minimize as much as possible the effects of gravity on the precision of the watch is taken to an even more extreme level.

The two double tourbillon systems further increase the averaging effect of the double tourbillon system. To achieve an even more obvious advantage, one of the two double tourbillons is inverted, so that the balance wheels are offset not only to the horizontal plane of the watch, but also to each other. The speeds of the two tourbillon systems are averaged through a differential mechanism to produce a more stable speed than that of each individual system.

The work done on the Quadruple Tourbillon à Différentiel then allowed Greubel Forsey to include the complication into other super sophisticated pieces such as the Invention Piece 2 or the Quadruple Tourbillon GMT, incredible from a visual point of view with the two systems of the double tourbillon and the miniature globe, which rotates once every 24 hours.

SUPPORTING INCLINATIONS

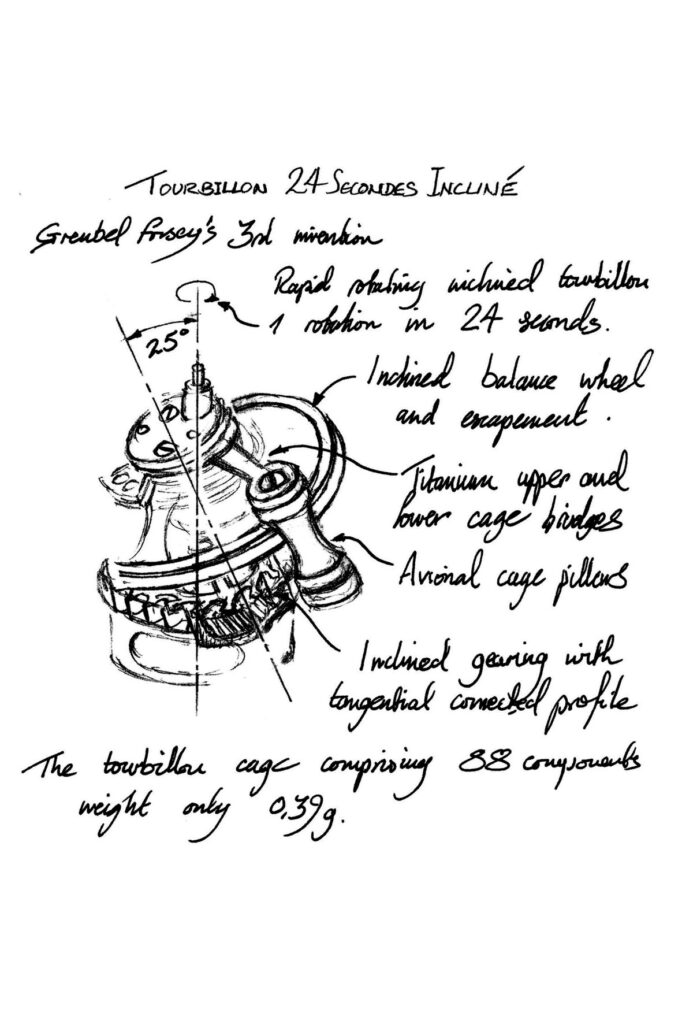

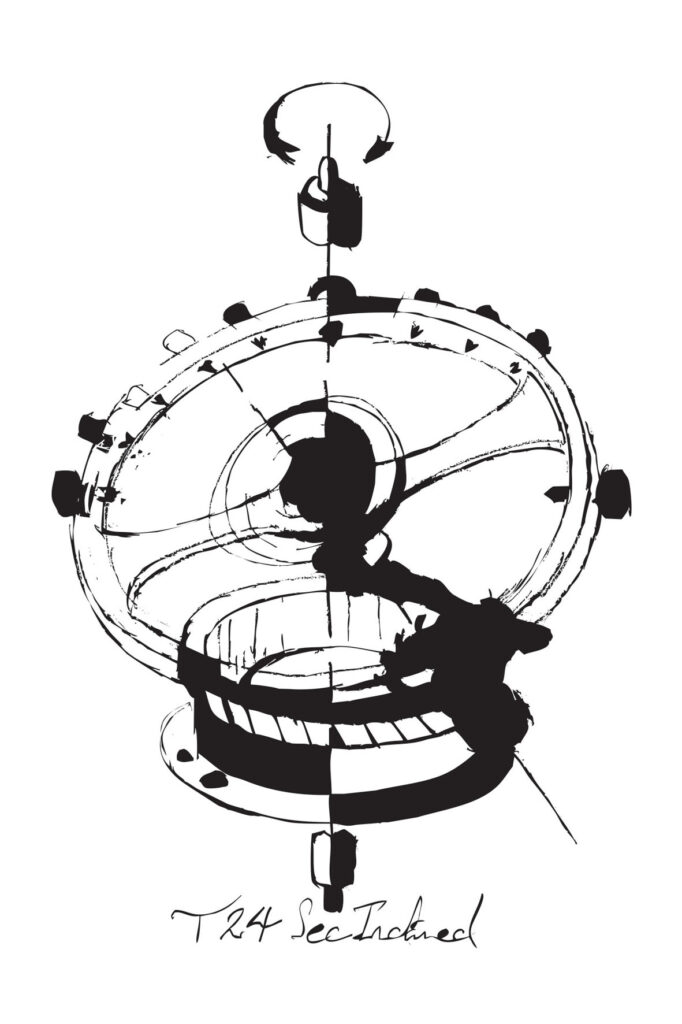

In 2007, Greubel Forsey’s third invention was created, the Tourbillon 24 Secondes. A technical solution that aimed, as in the case of the Double Tourbillon 30º and the Quadruple Tourbillon, at minimising the effects of gravity on precision. Only, this time, the solution came through a different path.

The double and quadruple tourbillons aimed to make the regulator system rotate in the broadest possible range of positions in order to avoid the negative effects of the most extreme ones: perfectly horizontal or perfectly vertical. The Tourbillon 24 Secondes is a mechanically much simpler system that perhaps takes a more direct approach.

While the mechanisms of the double and quadruple tourbillon used a very complex system of carriages one inside the other and – in the case of the quadruple tourbillon – of differentials, the Tourbillon 24 Secondes uses a single tourbillon, however inclined at 25º and which rotates very quickly: one revolution of the carriage every 24 seconds.

Although the solution is very different from that of the Double Tourbillon 30º and the Quadruple Tourbillon, the logic is the same: in this case the tourbillon rotates so rapidly that the chances of it spending significant time in any of the position extremes are almost zero.

GREUBEL FORSEY AND THE DIFFERENTIEL D’ÉGALITÉ

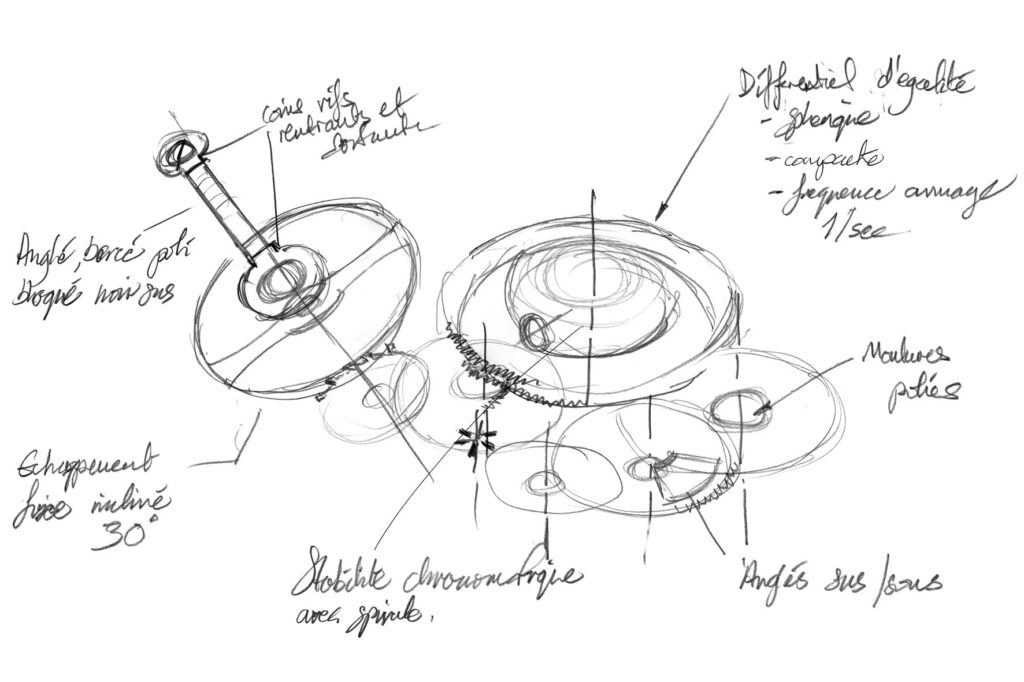

With the Différentiel d’Égalité, Greubel Forsey shifted their research from reducing the effects of gravity on the precision of a wristwatch to providing the energy needed to operate the balance wheel. For the solution, the two watchmakers started from a fact: all watches are driven by a main spring, whose spirals tighten when a watch is wound and unwind to power the gear train.

The problem is that the main spring tends to provide too much power when fully wound, and not enough when it reaches the end of its power reserve. Greubel Forsey tried to solve this by including a mechanism known as a remontoire, which is essentially another smaller spring positioned in the gear train, periodically wound by the main spring.

Since the remontoire is rewound frequently, it provides the system with more constant energy. However, power spikes still occur every time the remontoire is rewound; to overcome this, the watchmakers added a one-second differential system to the remontoire, so that power fluctuations in power delivery are kept to a minimum. In 2018, the Différentiel d’Égalité was enclosed in a watch of the same name.

COMING TO THE DOUBLE BALANCIER

With the Double Balancier we get closer to the present day and see the Atelier struggling with a new technical solution to the problem that the tourbillon is designed to face, but approached through a slightly different strategy.

The Double Balancier is not a watch with a tourbillon or a double tourbillon, but it is equipped with two balance wheels, both tilted at an angle of 30º. They are also angled in different directions, starting from the fact that if one balance wheel is located closer to one of the extreme positions (perfectly horizontal or perfectly vertical), its change in speed will be compensated for by the other balance wheel. The two are connected through a differential mechanism, which produces a single speed, the average of both balance wheels. It is a system used, for example, by the Double Balancier Convex, which we already wrote about on Watch Insanity.

THE EQUATION OF TIME

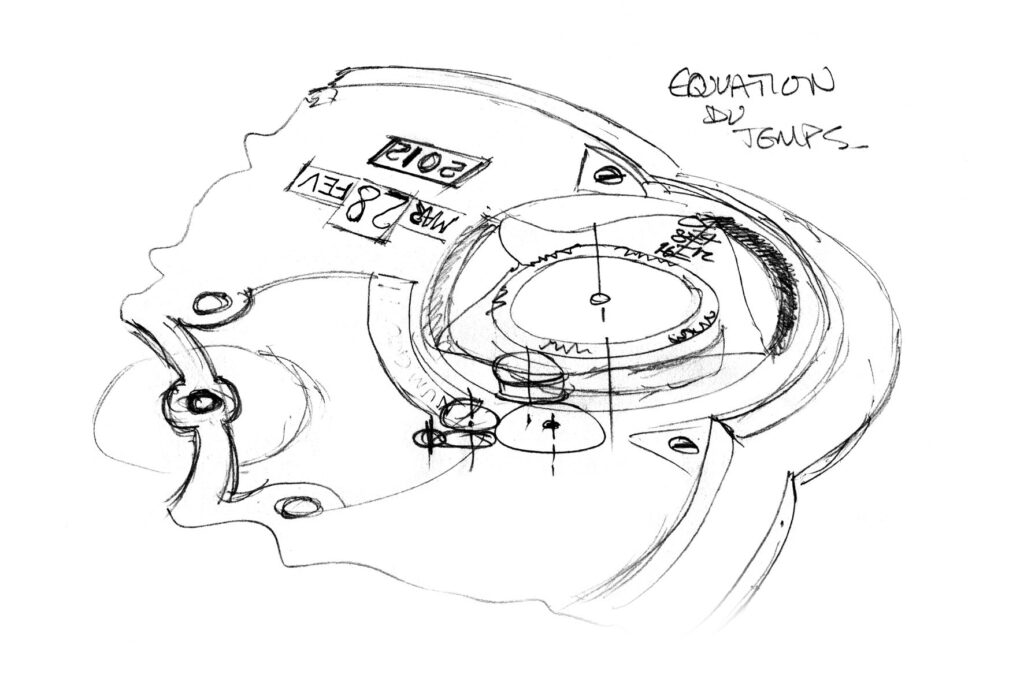

The QP à Équation, a watch with a perpetual calendar, a 25º inclined tourbillon and an indication for the equation of time, is characterized by what Greubel and Forsey called ‘Le Compteur Mécanique’. It is a system of overlapping gears that encode information intended for the perpetual calendar, including the length of each month, as well as the leap year change in February.

‘Le Compteur Mécanique’ activates a system of sapphire discs that show the equation of time and the current month. The watch also features a four-digit display of the year on the back of the movement.

Speaking of the equation of time, a not-so-common complication in watchmaking, the system that allows to calculate it in a timepiece is particularly complex. The equation of time shows the difference between the mean solar time and the apparent solar time – just as if we were reading the time on a sundial or on a watch. While the latter shows the average length of a day, i.e. 24 hours, the length of a day shown by a sundial varies slightly during the year due to variations in the Earth’s orbit and the inclination of the planet’s axis.

As you can imagine, this is a mechanical and mathematical virtuosity that only few brands are able to master. The fact that Greubel Forsey is among these is, in fact, not a surprise at all.

8 FUNDAMENTAL INVENTIONS

As you easily understand, nothing could better describe the approach to watchmaking taken by Greubel Forsey than the word invention. Since the beginning, Greubel Forsey rejected the notion that everything had already been created and embarked on a quest that was essentially, but not exclusively, focused on chronometry.

That research has led to eight fundamental inventions which we summarize here to provide a final overview of the atelier’s work: 2004 – Double Tourbillon Technique 30°; 2005 – Quadruple Tourbillon; 2006 – Tourbillon 24 Secondes; 2007 – Balancier Spiral Binôme; 2008 – Différentiel d’Égalité; 2009 – Double Balancier; 2015 – Compteur Mécanique; 2023 – Tourbillon Cardan.

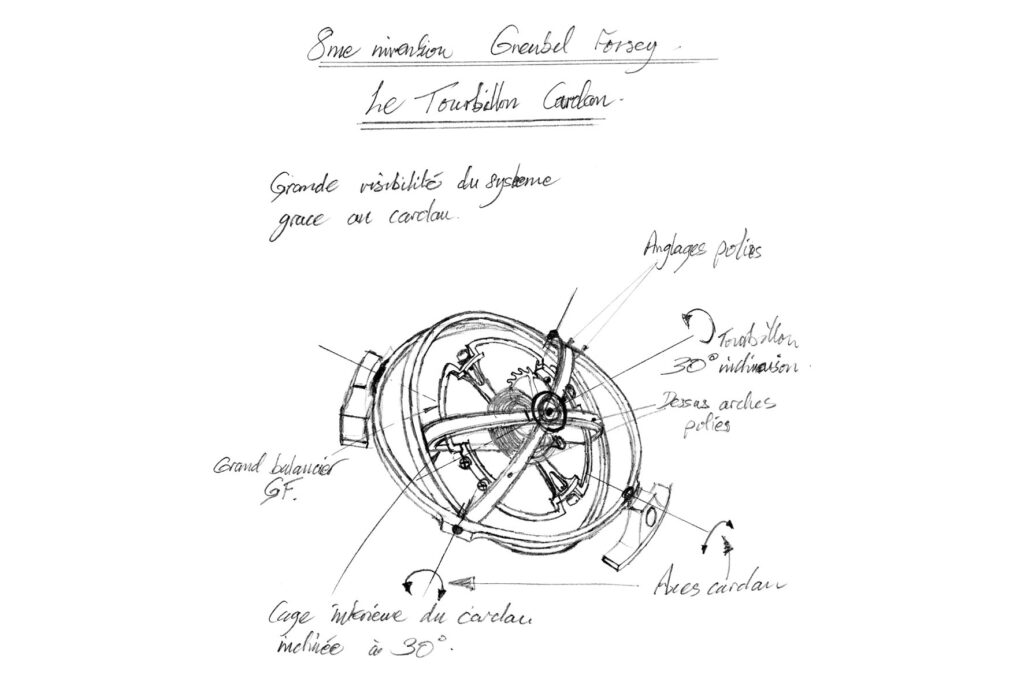

THE TOURBILLON CARDAN

It is worth focusing for a moment on the most recent, the Tourbillon Cardan, and seeing the main characteristics that make it unique. The Tourbillon Cardan combines three principles. The first: the tourbillon. While most tourbillons have a revolution of 60 seconds, that of the 8th Fundamental Invention is almost four times faster. Just 16 seconds. This is the fastest yet for a Greubel Forsey tourbillon.

This tourbillon incorporates, for the very first time, the large balance wheel designed, developed and made in-house by Greubel Forsey. It benefits from the exemplary balance of its masses, its large size (12.6 mm) and its optimised oscillations. Its high inertia also makes it less sensitive to shocks and variations in speed.

Second principle: the 30° angle. The tourbillon, as it was conceived over two centuries ago, was designed for pocket watches worn vertically. For a wristwatch, its design needed to be totally rethought, optimised for the positions adopted in everyday 21st century life. The 30° angle is the most effective of these optimisations.

Third principle: this 30° high-speed tourbillon is guided by two mobile rings, linked by two 90° axes. They tilt backwards and forwards in 48 seconds. On the Tourbillon Cardan, the tilt of the rings is controlled (+30° to -30° range), while the degree of inclination of the tourbillon is tilted (also 30°) and never varies, offering a better angular velocity to chronometric performance ratio.

The Tourbillon Cardan has four barrels. They are coaxially stacked, with a slipping mainspring to prevent excess tension during winding. They offer 80 hours of power reserve.

PLENTY OF AWARDS FOR GREUBEL FORSEY

We could make a detailed list of all the characteristics of the other pieces and other mechanical marvels that Greubel Forsey was able to create in just under twenty years, but we would never finish. From the GMT Tourbillon to the Art Piece 1, from the Hand Made 1 to the Signature 1 to the Invention Pièce, each of them is a work of art. Which have won quite a few awards.

In 2007, the Invention Pièce 1 won the prize for the ‘Grand Complication Watch’ category awarded by the international magazine Revolution. Also in 2007, the Swiss magazine Montres Passion awarded the ‘Special Jury Prize – Watch of the Year’ to the Tourbillon 24 Secondes. In 2008, Revolution once again rewarded the Quadruple Tourbillon with the ‘Technical Achievement Award’.

In 2009, the Quadruple Tourbillon was also named best ‘Grand Complication Watch’ at the Grand Prix d’Horlogerie Asia, while the Double Tourbillon 30º won the ‘Grand Complication Watch’ award at the Grand Prix d’Horlogerie de Genève.

2011 and 2012 were the years of the Invention Pièce 2. In 2011, at the Watch World Awards in India, the timepiece won the award for best ‘Limited Edition Watch of the Year’, and Greubel Forsey was awarded for its ‘contribution to Haute Horlogerie’. The following year it won two awards: ‘Best Design Watch’ at the Middle East Premier Awards and ‘Grand Complication Watch’ at the Grand Prix d’Horlogerie de Genève. In Geneva again, two other awards for Greubel Forsey: ‘Mechanical Exception Watch’ for the Grande Sonnerie in 2018, and ‘Men’s Complications Watch’ in 2020 for Hand Made 1.

Antonio Calce joined the company in December 2020 as CEO and shareholder and carried the brand into a new era. He is the first CEO in the history of the company, with long work experiences at Piaget and Panerai, at the helm of Corum and of the Sowind group. Having understood the great potential of the brand, he has the task of accompanying it through the new technical and market challenges. The new path the brand is taking follows his vision and guidelines, together with the always present impulse of Robert Greubel, President of the Board.

THE MANUFACTURE GROWS

Since its creation, Greubel Forsey’s in-house R&D team has filed 68 patents in 20 years. They are all checked and validated by one dedicated in-house expert, and have been an integral part of the development of more than 30 movements, past and present.

Today, 22 people work in R&D, under the leadership of an R&D and Innovation Manager. They include a watchmaker, a watch prototype designer and two micro-mechanics who are exclusively dedicated to developing products outside the Master Plan, 100% independent of the Greubel Forsey collections production. A four-person pole with its own timetable, and its own teams and resources.

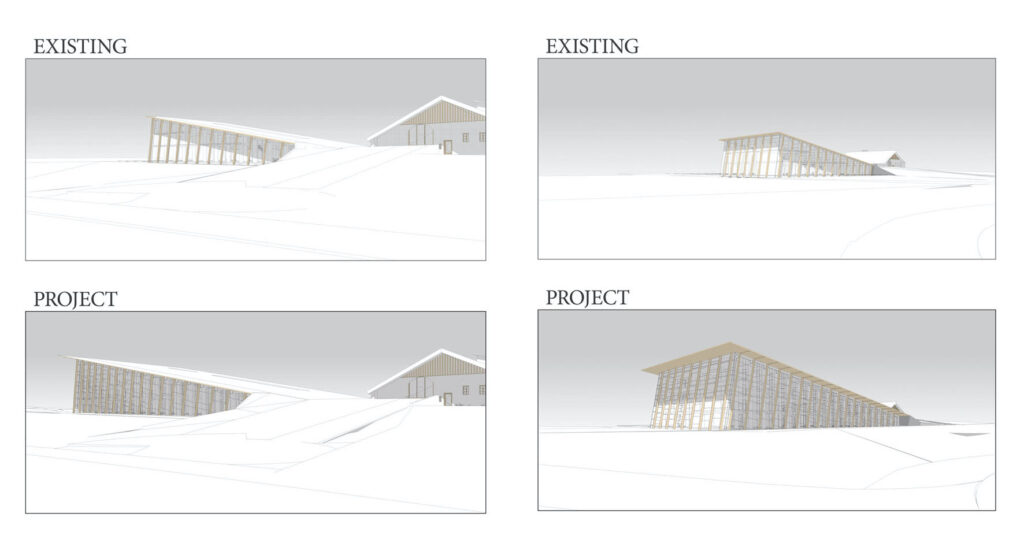

Moreover, Greubel Forsey’s Manufacture in La Chaux-de-Fonds will almost triple in size – thanks to an investment of 20 million Swiss francs – from 2,000 to 5,460 square meters. The expansion will enable the brand to develop new in-house skills and expertise, strengthen its research and development units, and gradually increase production capacity.

The new building will incorporate the existing structure, dating back to 2009, while retaining its architectural features. Construction is scheduled to begin in the first quarter of 2024, marking the brand’s 20th anniversary, and the new factory will be fully operational by 2026.

All this is enough to designate Greubel Forsey as one of the brands with the greatest refinement and technical research of the 21st century. Without bothering the legacy of Abraham-Louis Breguet with meaningless comparisons, Greubel Forsey’s approach to watchmaking is nevertheless destined to leave a mark on the entire industry in the years to come. The “Art of Invention” payoff couldn’t have been more appropriate.

By Davide Passoni