Inside the Renault Sport Formula One Team with Bell&Ross

11 July 2017Born and raised in Italy, we, at Watch Insanity, grew up with an insane passion for F1 and racing cars… Ok, not every Italian is an automotive fanatic, but 8 on 10 have been raised with bread and F1 Grand Prix… or at least we were!

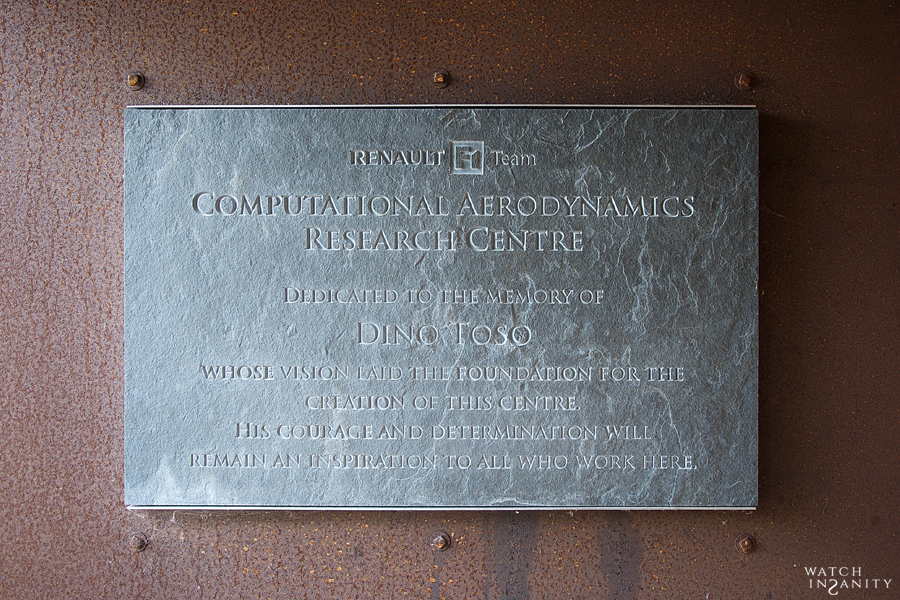

You can easily imagine how excited we were when Bell & Ross asked us to visit the Renault Sport Formula One Team Technical Centre in Enstone. For those who doesn’t know, Enstone is a place in Oxfordshire, England, that can be compared to the Silicon Valley for computers, and La Chaux-de-Fonds or Vallée de Joux for watchmaking, just saying…

In the early nineties, Formula One teams began to adopt a carbon fibre chassis, a revolution that improved the safety of the sport but that required much larger facilities to allow room for complex composite manufacturing facilities. The Benetton Team moved to the Whiteways Technical Center in 1992 and Enstone was chosen because of its privileged position, more than 3,500 companies associated with motorsport operates in the area.

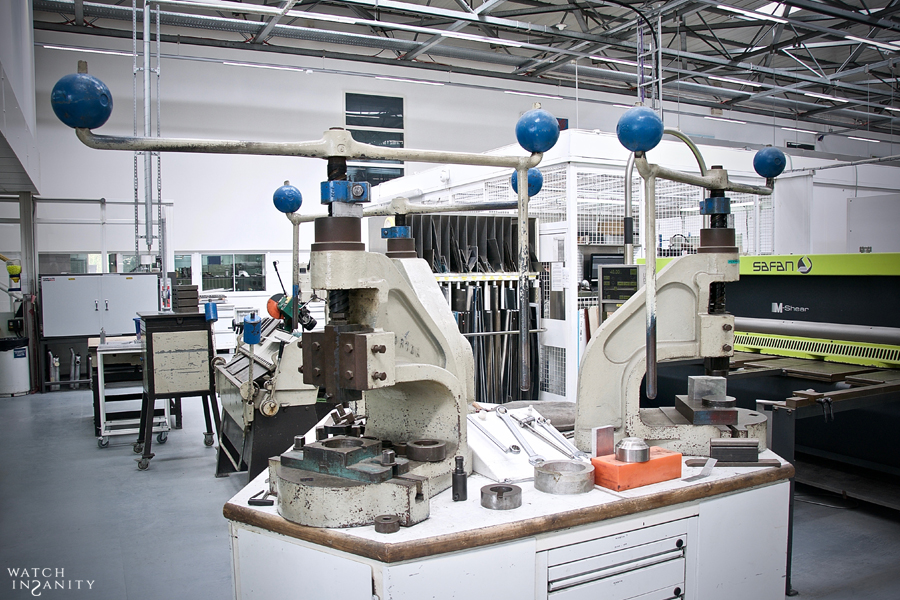

The manufacture is incredible, almost every component is produced and tested in-house. Every year, designing a Formula One car is a complex business, requiring more than 100,000 man hours and 12,000 CAD drawings to define approximately 6,000 components. Only the Design Office, or DO, have approximately 80 engineers specialized in different disciplines.

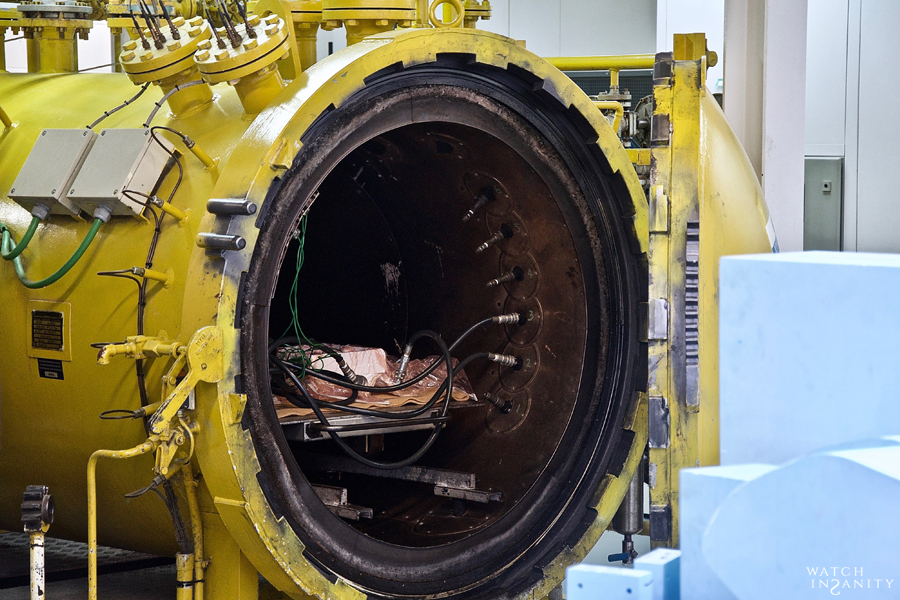

One of the coolest part is the Wind Tunnel, where the aerodynamic of the different components is tested, which is crucial for the F1… Every week more than 300 parts are tested by the team, and the air of the tunnel accelerates for over 10,000 HP. This is the biggest department Whiteways, and the team counts more than 100 employees.

The metal parts in a Formula One car are manufactured using light and strong metals and alloys like titanium, aluminium and Inconel, but 80% of the volume of the car is now in carbon fibre. Thank to its unique properties, such as a high tensile strength and lightness, carbon fibre became the most used component in motorsport, aircraft and aerospace.

This is the reason why Bell & Ross chose the same materials (forged carbon and high-tech ceramic) for the BR-RS17 collection, created in partnership with the Renault Motor Sport Formula One Team, and named after the team’s new R.S. 16 race car. The forged carbon case is produced with a delicate process, where the carbon fiber is compressed and a very high temperature creating a solid unique block of material, non-porous and water resistant.

The colors used for the BR-RS17 collection are inspired by the last Renault F1 cars as well, with a prevalence of black and yellow, of course!

The series includes three editions:

BR 03-94 RS17, 42mm chronograph with ceramic case and carbon fibre dial, limited edition of 500 pieces. (Price €.5.600,00)

BR-X1 RS17, 45mm chronograph with case in forged carbon and high-tech ceramic with rubber inserts. The dial is skeletonized and visible through a grey tinted sapphire crystal. Limited edition of 250 pieces. (Price €.22.000,00)

BR-X1 RS17 Tourbillon, 45mm case in forged carbon and high-tech ceramic with rubber inserts. Manual winding movement with Tourbillon escapement, column wheel chronograph with mono-pusher. Through the skeletonized dial is possible to see the escapement, the levers and the column wheel of the chronograph. Limited edition of 20 pieces. (€.159.000,00)