Seiko Spring Drive and Caliber 1210 by F.P. Journe: The Excellence of Quartz

22 March 2021Can quartz movements have the ambition to challenge mechanical calibers, be they manual or automatic, on the ground of value and elegance? After quartz has won the duel of precision since its appearance in watchmaking, some brands have tried to work on this technology to bring it to a manufacture level. Here, we focus on the two following examples: Seiko’s Spring Drive caliber and F.P. Journe.

SEIKO SPRING DRIVE: A 40-YEAR HISTORY

Seiko’s Spring Drive has its roots in the mid-1970s, at the height of the quartz era, when a watchmaker of the company, Yoshikazu Akahane, began to work on the design of a mechanical watch regulated by an integrated electronic device. He developed an idea called Quartz-Lock, to correct the errors of a mechanical watch using a standard quartz device integrated into it.

Akahane worked on the project for several years, creating hundreds of working prototypes and filing over 200 patents, but the problem he faced was the large expenditure of energy required by the system – due to the use of very energy-intensive integrated circuits – which involved a laughable power reserve. This led Seiko to shelve that technology for years.

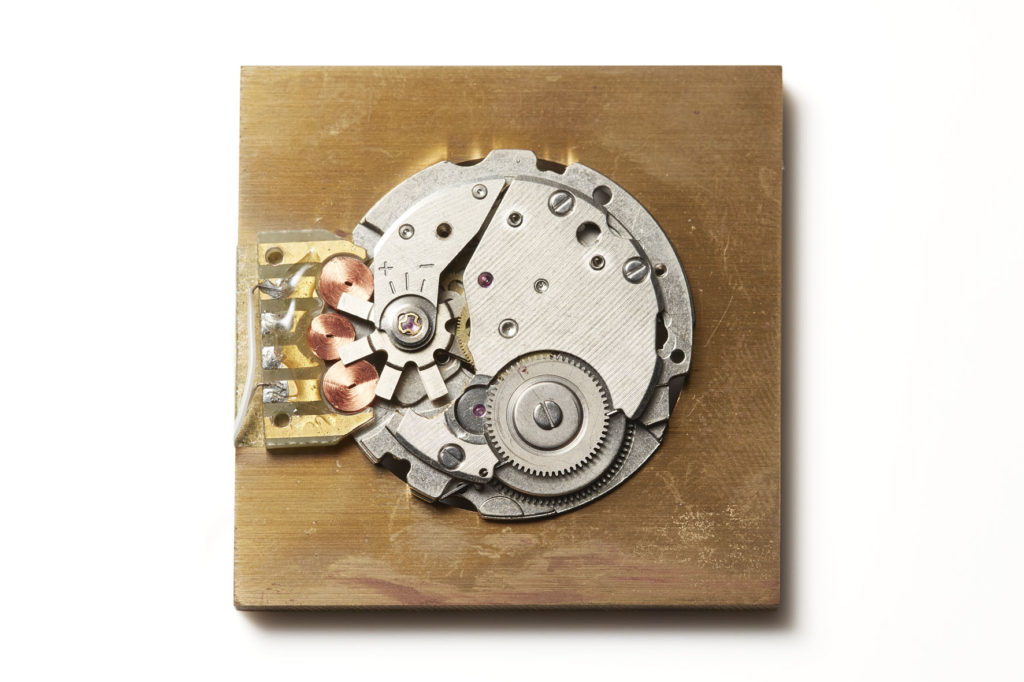

It was revived in two steps only in 1993 and 1997, thanks to the availability of new and more efficient integrated circuits, and the first Spring Drive caliber was presented by Seiko at Baselworld in 1998. A year earlier, the company had described the operation of the new technology in the Journal of the Swiss Society for Chronometry. Speaking of operation, then, how does the Spring Drive caliber work? Through a spring wound through a normal train of gears, regulated by an integrated circuit and a quartz oscillator.

1999 | First Spring Drive

A QUARTZ WITHOUT BATTERY

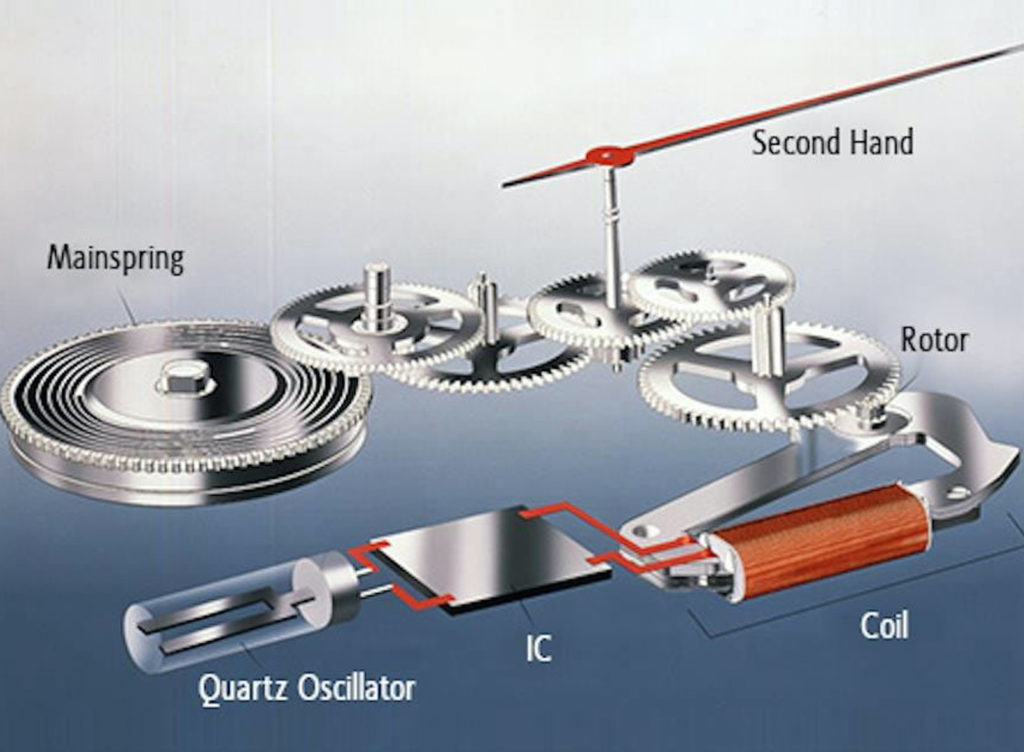

Its main feature is the fluid movement of the hands, especially that of the seconds; a fluidity that, for Seiko, “reproduces the intrinsic nature of time.” While a traditional electronic watch is powered by a battery and features a quartz oscillator that controls a step-motor linked to the hands, the Spring Drive movement, as its name implies, receives all the energy it ever needs for functioning from a wound spring.

Spring Drive watches have a mainspring with a power reserve of between two and eight days, just like a regular mechanical watch. Consequently, their mainspring is connected to a gear train, also very similar to the gear train which can be found in a traditional mechanical watch movement.

At the end of this gear train, there is a wheel that is not turning back and forth like a balance wheel does in a traditional mechanical movement but is instead turning continuously in one direction. How doesn’t this system lose accuracy?

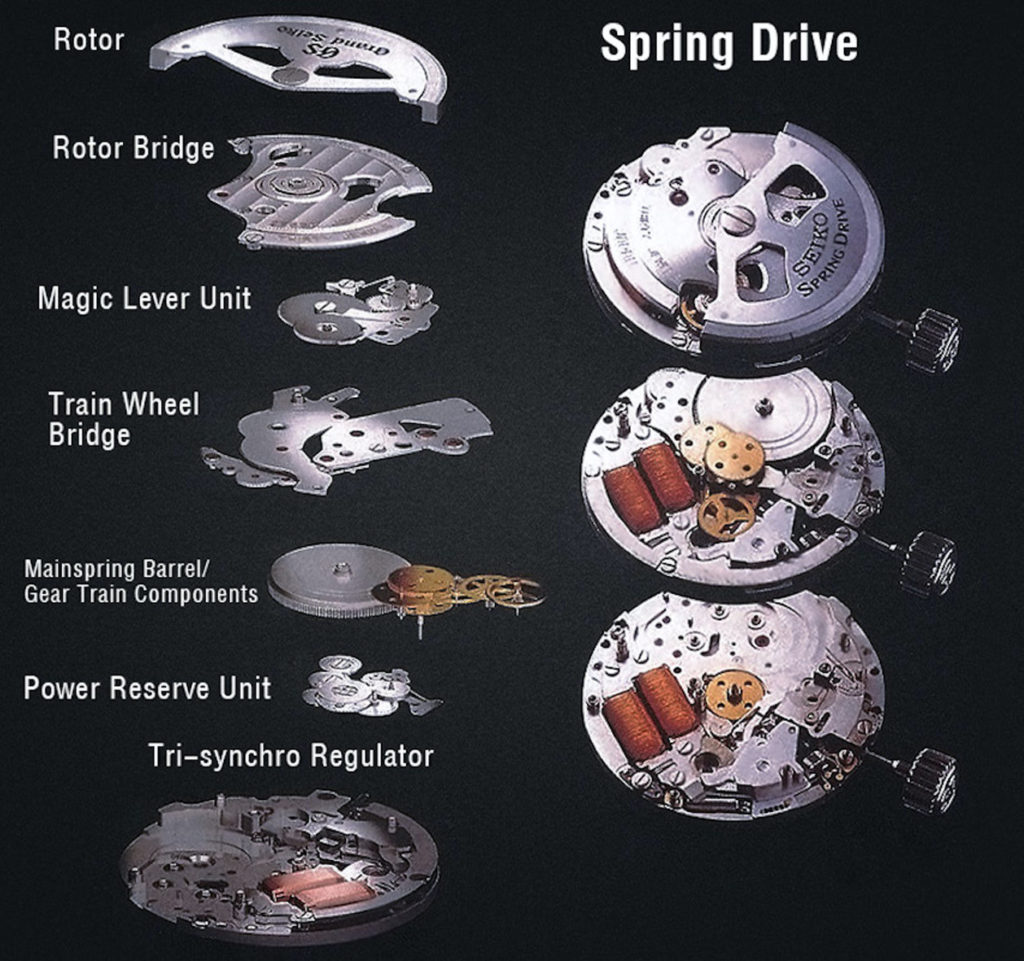

In a mechanical watch, the escapement and the balance wheel are responsible for tick-tocking at a set frequency, usually between 2.5 and 5 Hertz. In the Spring Drive system, instead, there is a so-called Tri-Synchro regulator, which controls three different types of power: mechanical power generated by the mainspring; electric power generated by an integrated chip and by a quartz oscillator; and electromagnetic power (rotor and stator).

The Tri-Synchro regulator controls and coordinates each of these three power sources, replaces the escapement used in almost all conventional mechanical watches, and moves the second hand smoothly and with extreme precision.

DURABLE AND RELIABLE

But, if there is no battery, how are the quartz oscillator and integrated circuit powered? The rotor, together with its coil blocks, acts as a power generator – working in the same way as a bicycle dynamo which generates electricity from a rotating wheel.

Electricity activates the integrated chip and the quartz oscillator linked to it, with the latter generating a reference signal of 32,786 Hertz. The chip compares this signal to the rotating speed of the rotor, which is eight turns per second.

With the necessary electric power and a reference signal to run the watch, we must ensure that the rotor, the gear train, and the watch’s hands rotate at the exact speed we want them to. For this, the Tri-Synchro regulator periodically applies an electromagnetic brake to ensure that the rotor’s rotation is aligned with the reference signal from the quartz oscillator. The chip monitor compares the rotor’s speed with the signal and intermittently applies this magnetic brake to prevent excessively fast rotation.

The hybrid nature of the movement should guarantee its reliability over time. According to Seiko, since the entire gear train rotates constantly and there is no traditional escapement with sensitive and lubricated parts, the movement should last a very long time.

Long life should also be expected for electronic parts, as there are no perishable chemical components, such as a battery, and because the way it works is comparable to that of long-lasting quartz movements

THE CALIBER 1210 BY F.P. JOURNE

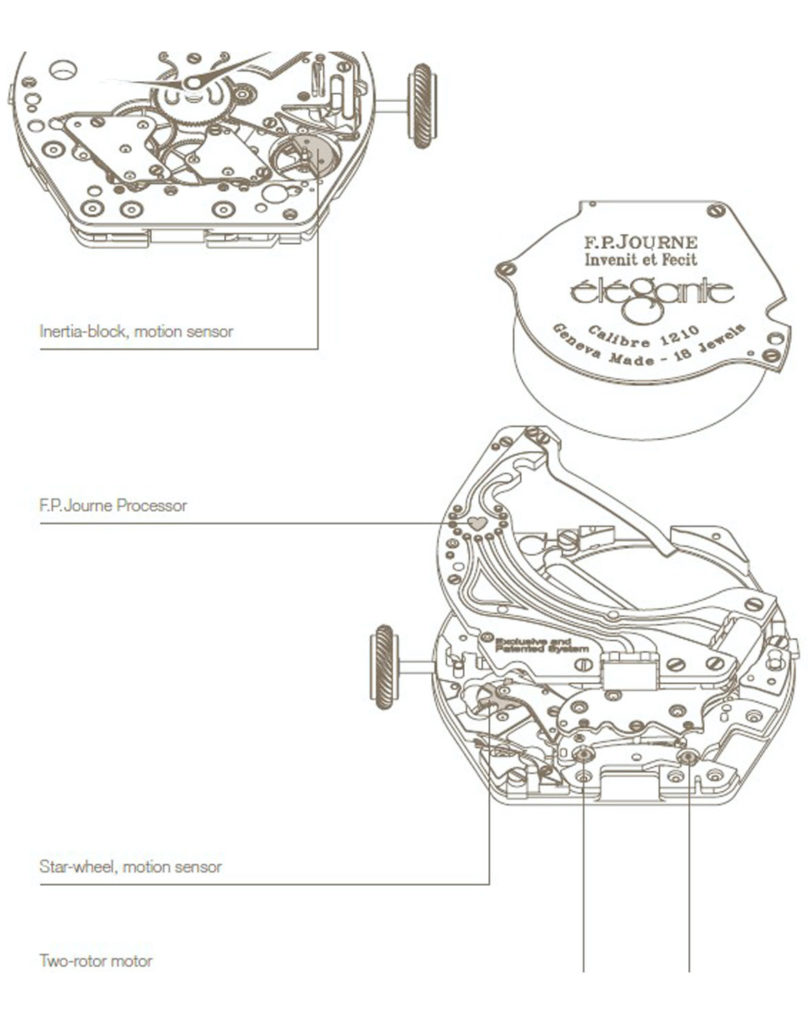

The caliber 1210 that equips the Élégante by F.P.Journe is a high-manufacture electromechanical movement. We have already written about the Tytalit version of the watch in recent months, which is why we will not go into the technical features of the caliber. Now we are mainly interested in highlighting some characteristics that differentiate it from the Spring Drive.

Here, unlike in the Seiko, there is a battery. And F.P. Journe created the caliber 1210 (after eight years of development) by designing himself even the battery, as well as all the components that help extend its life. The challenge of battery life is no different from that which are currently facing smartwatches.

In this case though, the power reserve runs on a different scale: the so-called “shelf life” of the Élégante (the life it would have if stored in a safe without ever being worn) is up to 18 years, with a guaranteed functionality if not worn daily for well over 8-10 years.

The watch uses a standard-size battery, albeit the one that has the highest lifetime rating at the time of the movement’s assembly, so the caliber – equipped with a patented two-rotor motor – does not rely on some proprietary or highly unusual battery technology. It is controlled by a microprocessor placed under the heart printed on the circuit plate, visible thanks to the see-through caseback.

SEPARATING AND SAVING, WITHOUT LUBRICATING

Battery life is increased by the use of two separate motors for the hour and minute hands. This choice is twofold. First of all, in a standard quartz watch only one motor is used together with the gear train. In the Élégante, on the contrary, the two motors make for shorter gear trains when compared to just one motor driving both hour and minute hands. With two wheels driving the hour and four driving the minute hands, the number of necessary components have been reduced to a minimum.

The second reason is lubrication. There is no point to extending battery life up to 16 years if the lubricants all degrade to beyond unusable in less than a third of that time. Friction increases when the oil loses its viscosity or dries over the years, and with increasing friction the consumption of energy also increases.

Therefore, the Élégante’s caliber 1210 doesn’t have any lubricated parts, making the parts virtually maintenance-free until the battery needs to be changed, that is after about 8 years.

START & STOP ACCORDING TO F.P. JOURNE

The key detail that helps the watch manage more than double-the-life-expectancy of the battery is the complication that stops the hands when the watch is resting, hence preserving its battery power.

In fact, the motors driving the hands consume by far the most energy in a quartz movement. Therefore, the Calibre 1210 senses when the watch has been stationary for more than 30-40 minutes and stops the motors from driving the hands, while the timekeeping functionality is still running, thanks to the integrated chip. Once the watch is picked up again, the motors drive the hour and minute hands in the shortest route possible to indicate the actual and accurate time, either clockwise or counter clockwise.

Stopping the hands is made possible by a mechanical movement detector, visible on the dial at 4:30. Created as a ladies’ watch, thanks to its particular electromechanical movement the Élégante meets the need of many women who wear wristwatches: to avoid wasting time to reset the hour and other indications when the power reserve runs out.

The battery cover and the bridges are in rose gold, embellished with the Côtes de Genève finishing, testifying how this quartz movement goes beyond the classic electromechanical ones. After all, could one expect something ordinary from Monsieur Journe?

By Davide Passoni